the Limits with Customization

Potential with Strength

of Attitude with Speed

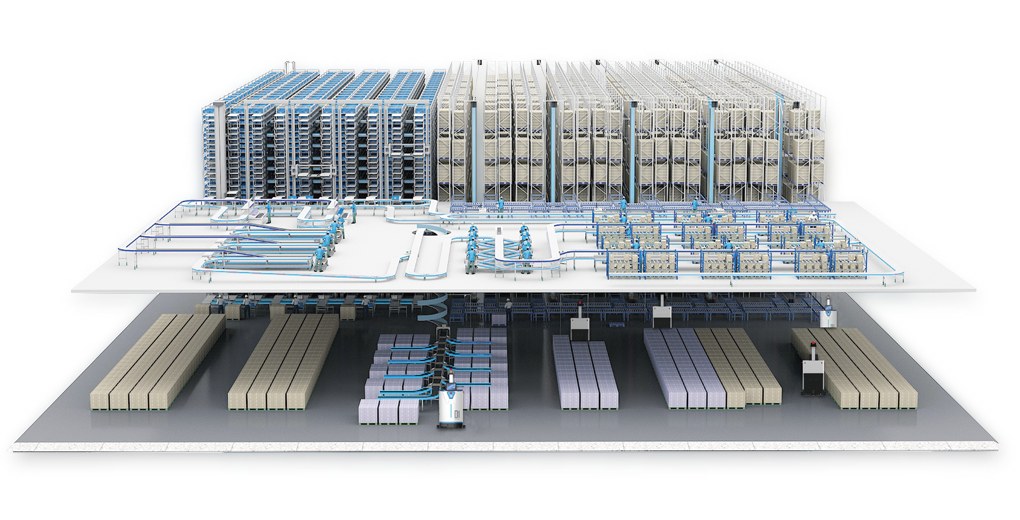

Solution: An automated warehouse is established by increasing the capacity per unit area in the existing plant height space to meet the demand for storage and retrieval of semi-finished products and finished products during the production, and match items demand efficiency in production lines, so as to improve product capacity and increase economic efficiency.

Equipment used: single-telescopic-boom stacker crane, double-telescopic-boom stacker crane, pallet four-way shuttle, AGV, and conveyor line

Advantages: increased inventory capacity, automated storage, and reduced labor costs

Solution: Wayzim uses automated picking and conveying equipment combined with PTL and RFID to achieve continuous storage of goods in depth on the shelves and the warehousing system in storage maximization. With a simple structure, low maintenance costs, and a very high storage rate. The solution effectively solves food conveying between production lines and warehouses, greatly improves the flexibility and efficiency of food processing and production, and allows considerable economic benefits to factories.

Equipment used: pallet stacker crane, four-way shuttle, and AGV

Advantages: any-location storage and retrieval, reduced losses by automated handling, and seamless connection between production lines

Solutions: In order to design a set of cost-effective expandable solutions that meet the needs of the shoes and clothing industry, the Warehousing Design Department of Wayzim tailors the project with solutions of the intelligent warehousing system integrating warehousing and distribution with a diverse range of robotic picking by dividing the warehouse into different areas after a detailed analysis of research data.

Equipment used: Pallet Stacker Crane, Four-Way Shuttle, Tote Stacker Crane, Tote Conveyor Line, and Pallet Conveyor Line

Advantages: integration of warehousing and distribution, full process tracing of goods, and vertical flexible sorting